Quality Service & Delivery since 1946

Stamping · Tooling · Assembly · Manufacturing

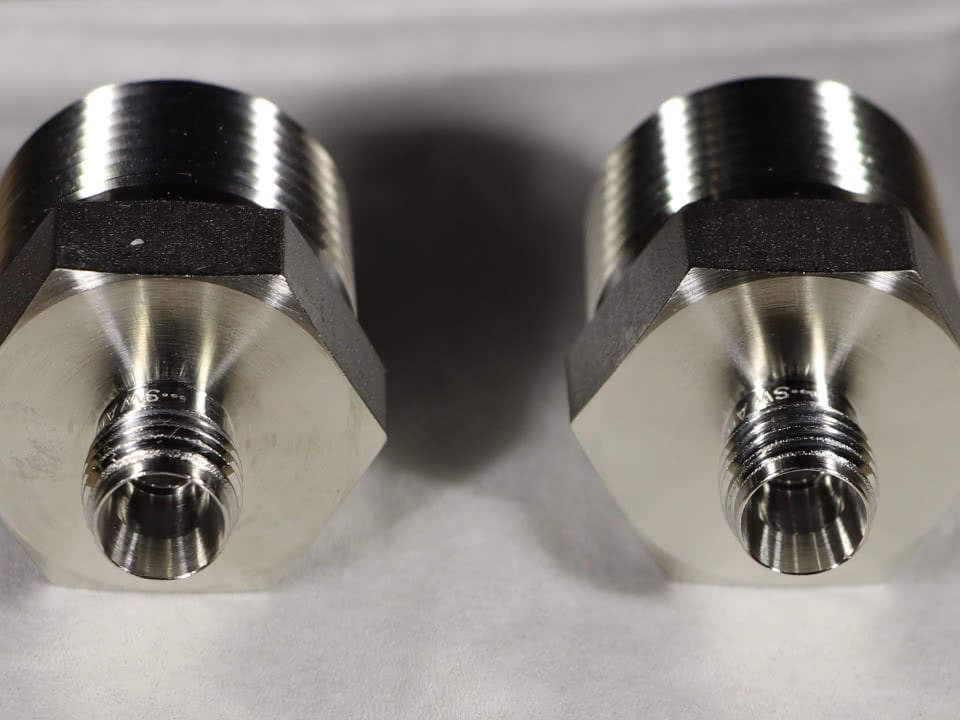

Stever Locke is a metal stamping manufacturer with niche electrical terminal & connector capabilities and a world wide customer base. We are relationship focused and don't miss delivery dates. We are capable of both low and high volume jobs, producing 1,000 - 7,000 units per hour. We guarantee our work with free tooling maintenance for the life of tools built by our process.

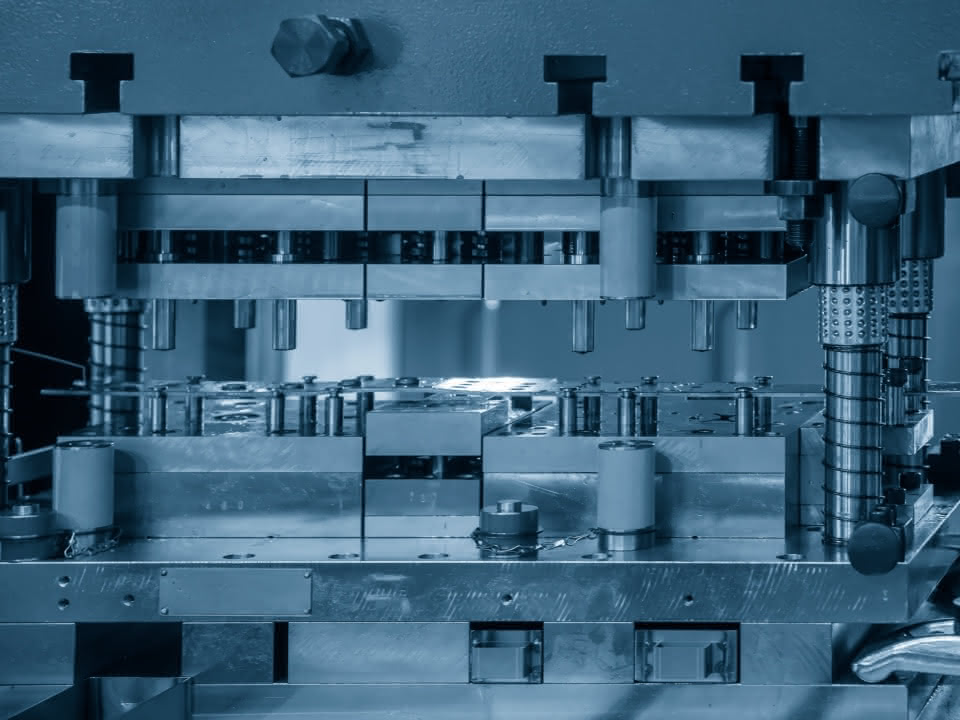

Equipment

- 30+ Punch Presses

- 50+ Secondary Machines

- Press Ratings 18-60 ton

Part Specifications

- Part Thickness: Min .004" up to .100"

- Can hold Dimension tolerance: +/- .0005"

- Part width: Max 32"

- Part length: up to 35"

- Can hold tolerance on Angles: +/- 1/2 deg

- Bed Length: up to 5h x 32w x 35.5

- Hot-Leaf Stamping

Certifications

Capabilities & Offerings

Quotation

Concise, detailed, and accurate. Typical turn around within 5 business days.

Project Management

We work with you and for you. Establish expectations and process. Continuous contact at multiple levels. Responsive and professional. Become your business partner.

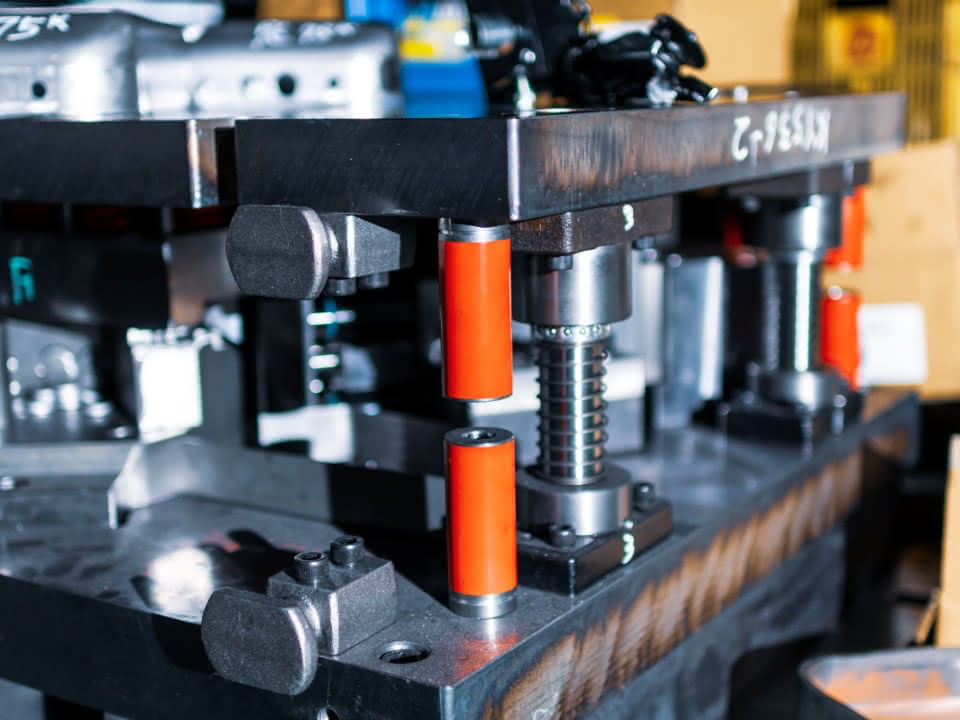

Tool Room / Tool Transfer

Fully equipped tool room with lathes, mills, drills grinding machines, boring machines, among others. Perform routine maintenance and properly inspect tools. Flexibility to help transfer customer operations to our facility with a tool move, greatly reducing downtime.

Quality Control

ISO9001. ITAR Registered. QS9000 / AS9100 Compliant. PPAP & PSO Certifications. RoHS & REACH Compliant.

Secondary Services

Connecting and attaching parts, subassemblies, and modules in specific sequence to produce a finished machine or part.

Assembly

Removing burrs, or rough-edged material through techniques like thermal, mechanical, electrochemical, and manual.

Deburring

Utilizes a high powered wheel to produce extremely fine finishes and outstandingly accurate dimensions.

Grinding

A process used to track parts inventory and reorders whereby items are grouped, packaged, and supplied together as one unit.

Kitting

Reduces the surface chemical reactivity of a metal leaving only the desired surface layer materials.

Outsource Passivation

Covering a material with a thin layer of metal for inhibiting corrosion, reducing friction, hardening, decorative factors, improving weatherability, altering conductivity, etc.

Outsource Plating

Die Types

Blanking

Producing a flat piece of material by cutting the desired shape in one operation. The finished edges of the part produces a uniform appearance as opposed to varying degrees of burnishing from multiple operations. Due to the even compression of the blanking process, the end result is a flat part that may retain a specific level of flatness for additional manufacturing operations.

Form

Takes a blank or piece of material and through one press stroke can create a shape out of the material. At times multiple form dies can be used to make the final production part.

Compound

Feeding a strip of metal through the compound die, which punches out a part in a single stroke. Compound dies can cut complex parts all in one stroke, eliminating the need for multiple dies. By creating parts with one die, we’re able to ensure consistency. Because compound dies can produce your part quickly and effortlessly, you can expect to save money.

Progressive

Feeding a coil of flat, thin metal stock into a stamping machine. Holes are pierced, contours are cut, and bends are made while advancing the part through sequential stations via a narrow carrier ribbon of material. At the end of the line, the part or parts are cut off, producing one or more custom metal stampings per cycle of the machine.

Industries Served

Aerospace & Military

Automotive

Consumer Products

Commercial

Electrical / Electronic

Heavy Truck & Off Road

Industrial

Medical

Materials Processed

- Aluminum

- Adhesives

- Beryllium

- Bi-Metals

- Brass

- Bronze

- Carbon Steel

- Coated Metals

- Copper

- Fiberboards

- Glass Polyester

- Gliding Metal

- Industrial

- Laminates & Paper Materials

- Insulation Boards

- Lexan

- Mica

- Mylar

- Nomex

- PVC Acetates

- Pre-painted Metals

- Plastics

- Phosphor-Bronze

- Spring Steel

- Stainless Steel

Contact Us

Document Downloads

Looking for our standard agreements? Download a copy here.